Introduction Narrator:

Hello everyone! Today, we’re bringing you another story of wisdom and laughter from the world of manufacturing. Have you ever faced those moments where you go, “Wait, how did this happen?” Well, today’s tale is one of those moments. Watch as Nonordinary Kenni and AI Steel Cat battle their way through a massive product defect crisis. How did they survive producing 400 defective parts? Let’s dive right in! Oh, and by the way, Kenni’s new name is Nonordinary Kenni from now on.

Dialogue

AI Steel Cat:

“Alright, alright! Today we’re diving into a serious press trouble story. It’s called ‘The Angel and Tragedy of Stainless Steel Shells.’ So, Nonordinary Kenni, what exactly happened?”

Nonordinary Kenni:

“Whoa there, Steel Cat! What’s with that dramatic title? (laughs) But yeah, this one’s serious. We were working on a SUS304 bending product with a 1.5mm plate. And boom—trouble hit! We ended up with 400 defective parts.”

AI Steel Cat:

“400 parts!? Whoa, that’s like ‘The Great Tragedy of 400,’ right?”

Nonordinary Kenni:

“Tragedy? More like catastrophe! When you have 400 bad parts in the middle of production, everyone turns pale. The L-shaped bending die broke, and the bending position shifted without anyone noticing. Production kept going and… well, you can imagine the mess.”

AI Steel Cat:

“Let me get this straight. An L-shaped bending die that’s no longer L-shaped? Yikes!”

Nonordinary Kenni:

“Exactly! The operators might have thought, ‘Hmm, something feels off today,’ but they didn’t catch it in time. And before you know it—bam!—a mountain of defective parts.”

AI Steel Cat:

“Wow… that’s not mass production; that’s mass destruction! (laughs) So, how did you handle the defective parts?”

Nonordinary Kenni:

“First, we tried a quick fix with the bender, using the notch on the bending position as a guide. But nope, the deformation wouldn’t go away. We had to stop the trial.”

AI Steel Cat:

“Hmm. So much for a quick fix. It ended up being… a quick fail.”

Nonordinary Kenni:

“You got it. Next, we tried a 90-degree V-bend punch. But the bending position shifted again, and the height increased by 1mm. Another fail.”

AI Steel Cat:

“Wow, this problem sure is stubborn. Even the V-bend punch threw in the towel!”

Nonordinary Kenni:

“Finally, we made a temporary L-bending die and gave it another shot. This time, we added a urethane clamp to hold the workpiece and used the punch to fix the surface. It worked, and we finally got good parts.”

AI Steel Cat:

“Phew! That was a long road to success. But it looks like you nailed it in the end!”

Nonordinary Kenni:

“Yeah, but these kinds of troubles are hard to prevent entirely. That’s why having strong fundamental technical skills and creative problem-solving is essential.”

AI Steel Cat:

“Ah, I see! Experience and adaptability really make the difference in a crisis.”

Conclusion Narrator:

What an intense story, huh? Once again, Nonordinary Kenni and AI Steel Cat showed us the importance of quick thinking and solid technical skills on the shop floor. Remember, no matter what challenges you face, staying calm and creative can turn things around. Keep honing your “field expertise”! See you next time!

Today’s Manufacturing Theme: Troubleshooting Bending with SUS304-2B Material (1.5mm Thickness)

Today’s topic revolves around a major issue that occurred during the production of SUS304 bending parts. During a run of 400 units, the L-shaped bending die broke, causing defective parts to pile up. Here’s how we tackled the problem step by step.

Steps for Corrective Actions:

- Attempting Additional Bending:

- Tried using the bending position notch as a guide for a secondary bending operation. Unfortunately, the deformation couldn’t be corrected.

- Using a 90-degree V-Bend Punch:

- Tried using a 90-degree V-bend punch at the notch position. The result was further deformation and a shift in bending height by 1mm. This trial also failed.

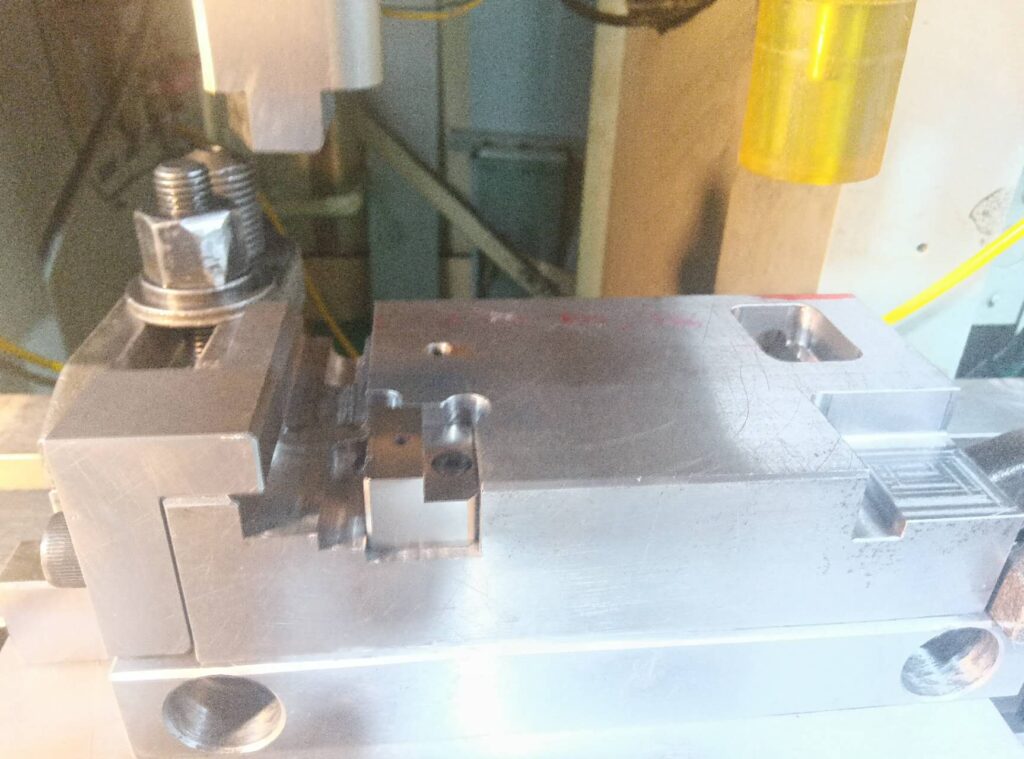

- Temporary L-Bending Die:

- Created a temporary L-bending die and performed another trial.

- Improved deformation control and achieved near-spec results.

- Added a urethane clamp and conducted surface correction with a punch, leading to successful parts.

Key Takeaway:

While it’s difficult to prevent all troubles beforehand, having the ability to quickly respond with creative ideas and foundational technical skills is crucial for success.