Burring is a persistent challenge in punching operations, yet its formation mechanism is often misunderstood. Today, AI Steel Cat and Keni the Amazing dive deep into the truth behind burring! Through a fun yet insightful discussion, filled with humor and technical insights, we take you on a journey into the depths of the manufacturing floor.

AI Steel Cat

“Alright, Keni! Today, let’s dig into the topic of ‘burring’ in punching operations. Generally, it’s explained that burring occurs when the punch penetrates the material, causing plastic deformation that pushes out the material surface. But is that really all there is to it?”

Keni the Amazing

“Let me tell you the truth. AI Steel Cat, thinking that burring is just a surface issue is like saying ‘just grilling a hamburger makes it delicious’—it’s too simplistic. The real cause of burring lies in the internal material flow.”

AI Steel Cat

“Internal material flow… That’s intriguing! Could you explain that in more detail?”

For more details, please visit: APT GIKEN – YouTube

Keni the Amazing

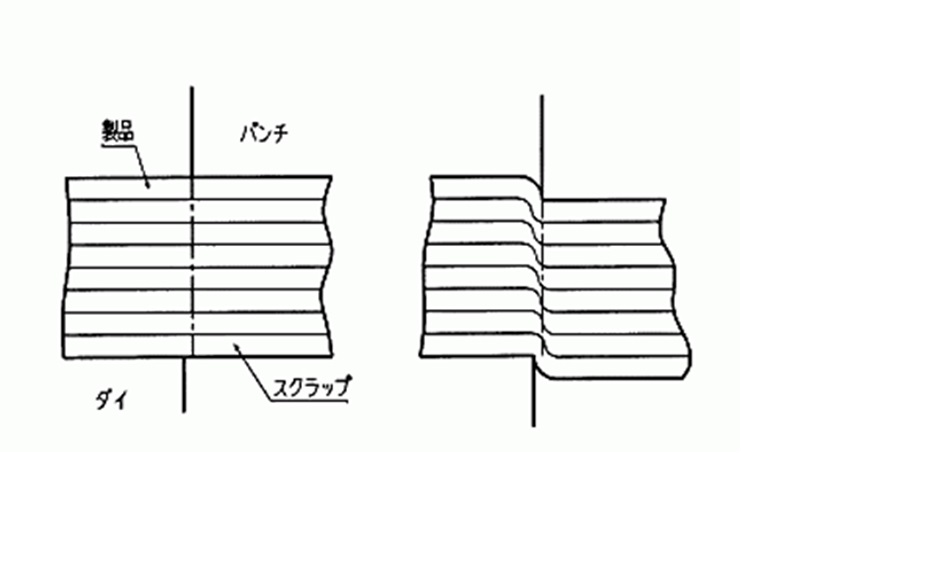

“Listen carefully—when the punch starts penetrating the material, the initial burr is small. But as the material gets pulled by the punch’s movement, internal flow begins. Even areas far from the punch tip start to move. This overall material flow, pulling downward with the punch, is what causes the burr to grow.”

AI Steel Cat

“So the entire material moves? That’s something you wouldn’t notice just by looking at the surface! It’s like a leader calling for followers: ‘Come on, everyone, move with me!’ (laughs).”

Keni the Amazing

“Exactly! When material near the cutting edge deforms, surrounding material gets pulled along too. This movement is what ‘feeds’ the burr.”

AI Steel Cat

“Got it! But the shape of the punched hole must also affect burr formation, right? Does leadership play a role here too?”

Keni the Amazing

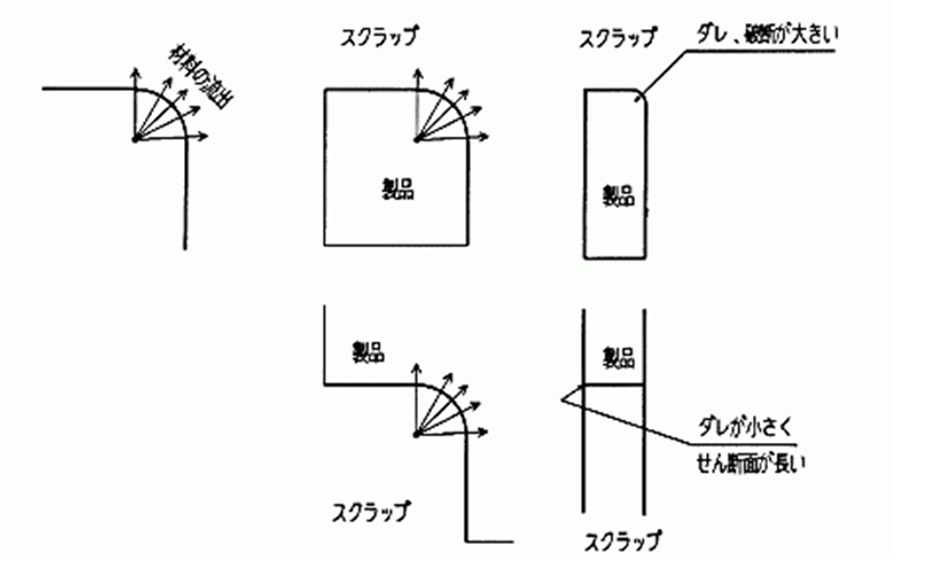

“Leadership? Not really, but the hole shape definitely matters. For instance, when punching a hole with a radius equal to the material thickness, the amount of burring differs significantly between inner R and outer R shapes.

- Inner R: The material is pulled inward, limiting its movement, resulting in smaller burrs.

- Outer R: The material is pushed outward, increasing flow and leading to larger burrs.”

AI Steel Cat

“Interesting! But why does the material flow outward more in outer R shapes? Is it just ‘the way of nature’?”

Keni the Amazing

“More like ‘taking the path of least resistance.’ In an outer R shape, the force from the punch naturally pushes the material outward, causing it to spread.

On the other hand, an inner R shape restricts the material’s movement, preventing excessive flow. This is why the burr size varies.”

For more details, please visit: APT GIKEN – YouTube

AI Steel Cat

“Now I see! The ‘escape route’ for the material is key. Materials are quite clever, aren’t they? (laughs)”

Keni the Amazing

“Yes, materials can be surprisingly tricky! But if you don’t understand their behavior, you’ll never control burring. In manufacturing, it all comes down to understanding movement.”

AI Steel Cat

“Every time you explain this, I’m amazed, Keni! Readers will definitely gain new insights into manufacturing processes. Materials behave just like skilled workers—they perform best when given clear direction but waste energy when guidance is unclear.”

Keni the Amazing

“Hey now, that sounds a bit condescending! (laughs) But you’re right—just like experienced craftsmen, materials need structure and direction. This understanding is crucial for controlling burrs. I hope this discussion helps those in the field!”

For more details, please visit: APT GIKEN – YouTube

Final Thoughts

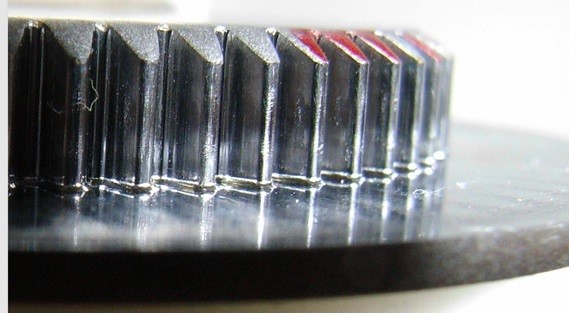

Burring in punching operations isn’t just about surface plastic deformation; internal material flow is the key factor.

By understanding the direction and volume of this flow, we can develop better strategies for controlling burrs.

Next time, AI Steel Cat and Keni the Amazing will discuss ways to reduce or eliminate burrs. Stay tuned!